Reactivity and corrosion of refractories used in metallurgy: steel-making, non-ferrous, foundry.

Impact on cleanliness and metal quality.

Refractory products are not only strategic for the production of metals and alloys, but they also have a direct influence on the quality of elaborate grades.

This Fire course reviews the impact of reactivity and corrosion on :

- the refractory wear

- the inclusionary cleanliness and quality of metallurgical products.

It mentions all the important developments that will limit the contribution of refractory products concerning wear, oxide cleanliness, steel desulphurisation, Ca treatments of alumina de-oxidation inclusions, carbon pick up for ultra-low carbon steel, clogging phenomena and atmospheric oxidation, in conjunction with efforts of the metallurgists to produce clean alloys.

The course is focused on

- Students with study majors in refractory and ceramic engineering, metallurgy and materials (Master or PhD level)

- Interested engineers with an employment in the refractory manufacturing or refractory consuming industry

- One focus is the iron and steel industry, but also other high temperature metallurgical processes are discussed.

The F.I.R.E Compendium series 2 “Corrosion of Refractories: The Fundamentals, Testing and Characterization Methods and the Impact of Corrosion will be provided to participants.

Date

October 17th. 2019,

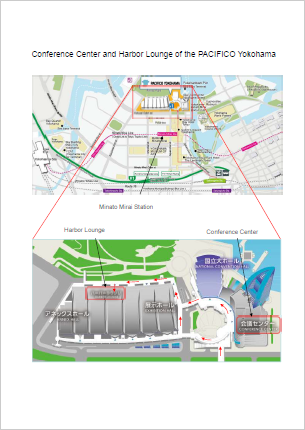

Venue

Registration Fees(per person)

Less than three people:

Without compendium books: 75,000

Including FIRE compendium volume 2a,2b,2c: 100,000

Three people or more:

Without books 68,000

Including FIRE compendium volume 2a,2b,2c: 95,000

* In order to enjoy the discount rate, the registrations must be done and paid in the same registration account with

the same ID(email address) and inquiry number.

After the conference, the amount of the discount will be credited to the credit card account used for the payment.

Registration Deadline

September 13th, 2019 (Japan time = GMT+09:00)

Cancellation Policy

A cancellation of the registration will be subject to the following cancellation fees.

- Through October 1st, 2019 … No cancellation fee (100% refund)

- After October 1st … 100% of the registration fee (No refund)

In case you fail to make payment by the due date, your Pre-registration will be cancelled.

Course descriptions

Introduction and context [08.00-8.15], J. Poirier

- Issues of refractory corrosion

- Degradation factors

- Characteristics and durability of refractories

Thermodynamics and metallurgical modelling [8.15-10:15], In-Ho Jung

- Basic knowledge of thermodynamics

- Slag structure and basicity

- Viscosity of slag

- Computational thermodynamics

- Refractory corrosion applications

Break

The fundamental mechanisms of corrosion and the solutions to limit the thermochemical degradations [10.30-12.00], J. Poirier

- Corrosion by liquid species (metal, slag, molten salts)

Transformation of phases

Direct and indirect dissolution, dissolution with precipitation of new compounds, growth of reaction layers

Oxido-reduction, carbo reduction, oxo reduction, Protective in-situ reactions

Microstructures of corroded refractories, industrial examples - Corrosion by gaseous species

The mechanisms: direct attack, condensation of gas and formation of corrosive liquid phases

Formation of a protective layer or structural spalling

The reactions: oxidation, reduction, dissociation, volatilization

Microstructures of corroded refractories, Industrial examples

Lunch

Testing and characterization methods to study corrosion [13.00-14.30], E de Bilbao

- Traditional characterization Methods

- In situ and Advanced Characterization Methods

Impact of refractories corrosion on industrial processes [14.30-15.15]

Process optimization, In-Ho Jung

- Steelmaking

- non-ferrous metallurgy

Impact of refractories corrosion on metal quality, J Poirier

- Corrosion reactions between refractories, metal and slag

- Metallurgical consequences

- Steel desulphurization

- Ca treatments of alumina de oxidation inclusions

- Elaboration of ULC steels

- Flow control

Break

Impact of refractories corrosion on inclusionary cleanliness, Christos Aneziris [15:30-17:30]

- high temperature wettability

- Control and prevention of non-metallic inclusions

- Ceramic filters: design, efficiency, industrial results

Conclusion

Biography of the instructors

Prof. Christos Aneziris

Technical University Freiberg, Germany

Head of Ceramics at the Institute of Ceramics, Glass and Construction Materials

Born in Athens, Greece (05/05/1969)

Dipl.-Ing. Degree in Metallurgy, NTUA, 1992

Dr.-Ing., RWTH Aachen, 1996

Habilitation, RWTH Aachen, 2000

Prof. In-Ho Jung

Seoul National University, South Korea

Associate Professor in the department of Materials Science and Engineering

Born in Goseong, South Korea (01/04/1975)

M.Sc. degree in Material Science and Engineering, Postech, South Korea, 1999

Ph.D., Ecole Polytechnique de Montreal, Canada, 2003

Prof. Jacques Poirier

University of Orleans, France

Head of research group: Refractory Materials, design and corrosion, CEMHTI

Born in Rennes, France (07/04/1958)

M.Sc. degree in Material Science, INSA, 1980

Ph.D., University of Orleans, 1983

Assistant Professor Emmanuel de Bilbao

University of Orleans, France

Research group: Refractory Materials, design and corrosion, CEMHTI

Born in Bordeaux, France (27/01/1968)

M.Sc. degree at École Normale Supérieure of Cachan

Ph. D. at the University of Orléans in 2008